First Quick Qualification (FQQ)

Get Your First Tool Qualification Documents.

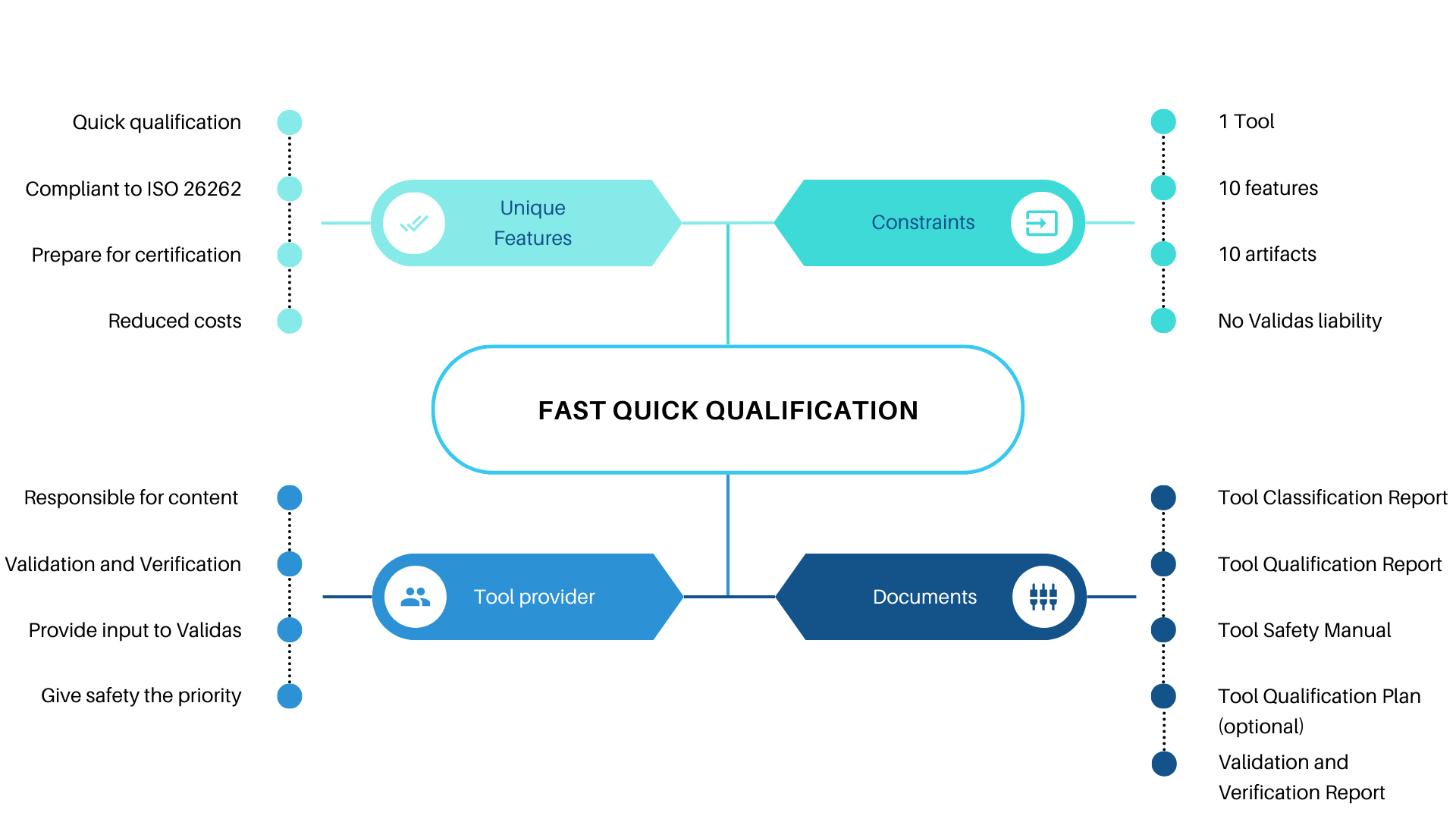

What is FQQ?

FQQ is a quick way to get your first Tool Qualification documents from Validas.

Validas will help you to generate the documents using Validas template and generators, but Validas will not take responsibility for the correctness of the contents as we usually do. You must not use our Logo on it. FQQ can be extended later to cover more features and versions of your tool, or even to build a qualification kit which can be used (and sold) to qualify the tool in customer environments.

Goals of FQQ

- Perform a First Quick Qualification of the most important features of your tool

- Get the required documents in PDF:

- Tool Classification Report (TCR)

- Optional (mandatory for IEC 61058) Tool Qualification Plan (TQP)

- Tool Qualification Report (TQR)

- Tool Safety Manual (TSM)

- Verification and Validation Report.

- Compliance Report with ISO 26262 (including a process report and reference to Validas TÜV certificate for this document)

- Be compliant with Safety Standard ISO 26262

- Take Responsibility for Correctness

- Learn about Tool Qualification Process

- Prepare a Tool Certification with TÜV

- First step towards a Reusable Qualification Kit

- Limitations:

- Validas does not perform Verification and Validation

- Validas does not guarantee success for TÜV certification

- Validas Logo must not be used on documents

- Number of features is limited to 1 tool with up to 10 features and 10 artifacts

Description

Validas will create a TCA model of the tool to ensure consistency of qualification and compliant documentation. Creating and validating the model “guides” through the process, for example to detect name clashes or missing mitigations. In order to be successful, we require the following contributions from the customer:

- Commitment to give safety the highest priority

- Provide the following inputs that Validas requires to create the model and generate the documents:

- General information about the tool (using Excel templates):

- Tool Structure Information (Tool-Artifact Matrix “TA-Matrix”) with

- List (or Tree) of safety relevant features (to be included in the use case)

- List of input and output artifacts (files, model, UI) used or created from the safety relevant features

- TA-Matrix (Excel)

- Participation in a Workshop with Validas to learn about tool qualification and test strategies

- Description and mitigation of potential errors (in all relevant features)

- Specification of test strategies for non-mitigated potential errors

- Independent person suffices (for ASIL B, for ASIL D this should be done from independent person that has power to stop the product release in case of blockers) technical review (Verification and Validation)

- Test results from executing the test cases in a ”golden run”

- Acceptance review of the provided documents from Validas

More information can be found in this podcast episode

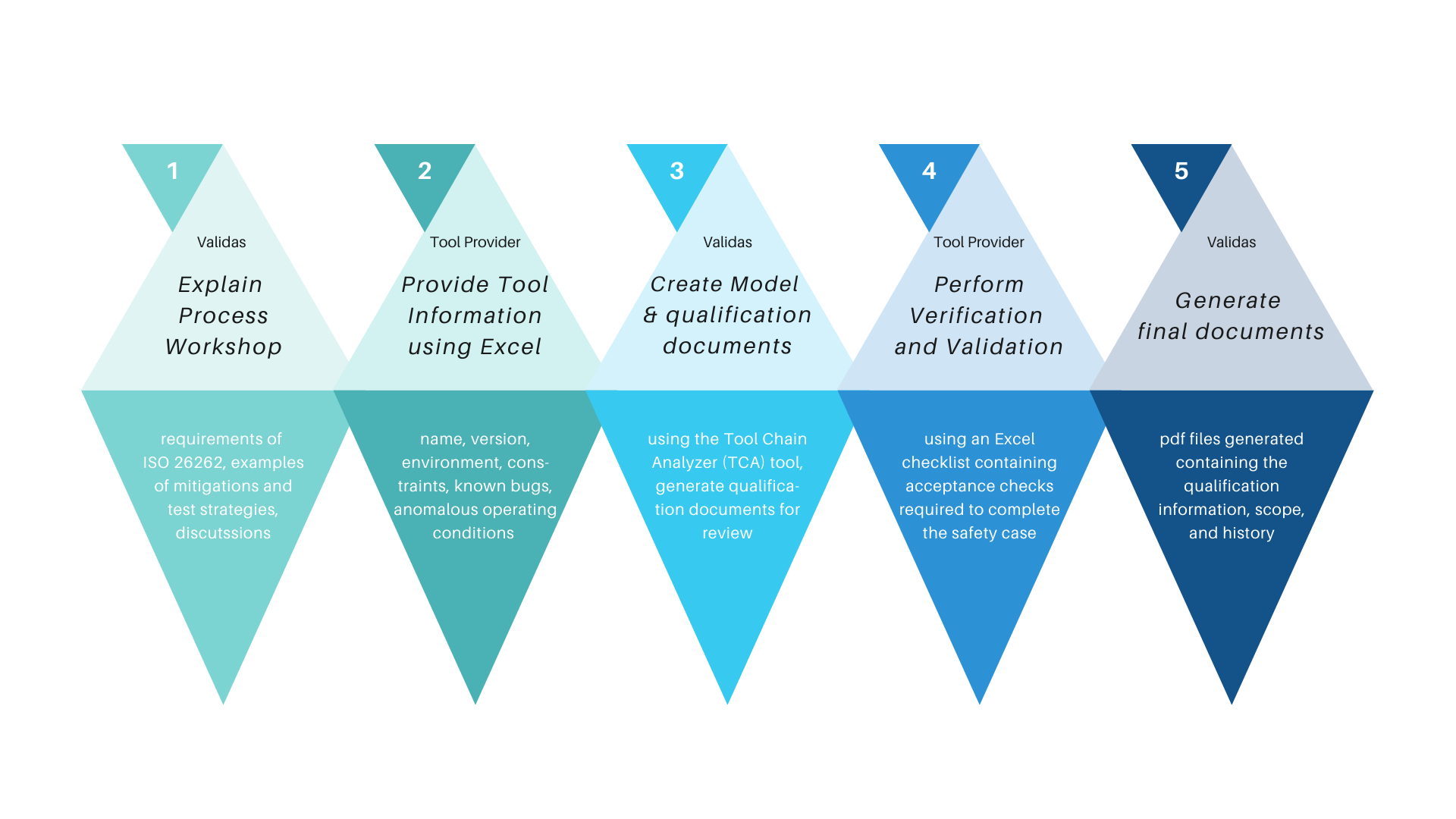

Process

We follow the Validas certified Tool Qualification Process in its most simple version:

- Validas: Explain Process (Workshop)

- Tool Provider: Provide Tool Information (using Excel)

- Validas: Create Model and Qualification Documents for Review

- Tool Provider: Perform Verification and Validation (using Excel)

- Validas: Generate Final Documents

Get More Information about FQQ with a tool qualification strategy talk (booking link)